It has been almost 10 months since the deadly April, 5, 2010 explosion at Massey Energy’s Upper Big Branch mine in Montcoal, West Virginia. Federal mine safety officials now say they have strong evidence showing that an initial methane ignition burned for 60 to 90 seconds before it set off a secondary powerful coal-dust-fueled explosion that tore through miles of underground tunnels, killing 29 miners.

The findings were given to family members of those killed and the media in two separate meetings held last week by federal officials for the Mine Safety and Health Administration. MSHA officials describe it as their “working theory” and say they are nearing the end of their investigation of the disaster.

Mine investigators believe that sparks given off from faulty bits on the longwall mining machine ignited a pocket of approximately 13 cubic feet of methane gas, which burned for 60 to 90 seconds. The burning methane ignited a massive amount of highly explosive and untreated coal dust, which was pervasive throughout the mine. It carried the blast throughout miles of underground pathways that twisted and turned, killing miners over two miles away from the point of ignition.

At least two miners were at the tailgate section of the longwall where the methane ignition started, but had time to telephone miners operating the longwall machine to tell them to power off the machine. They then ran about 400 to 500 feet before being killed by the coal dust explosion.

Investigators say this lends credence to their estimates of a 60- to 90-second time lapse between ignition of the methane gas and the fatal explosion.

This briefings for family members and reporters were the first since a similar set of meetings was held four months ago, last September. MSHA officials said they are nearly finished with the investigation. While over 260 people have been interviewed, 18 Massey officials have refused to testify, citing their Fifth Amendment rights.

MSHA officials have also reiterated a decision made earlier in the week to postpone indefinitely a public hearing into the tragedy, or to make public the transcripts of those interviewed. MSHA director Joe Main stated that this was being done at the request of the Justice Department, which is conducting a criminal investigation into the explosion. Both the Justice Department and MSHA are part of the Obama administration.

At no time in previous MSHA investigations has this interfered with a criminal investigation. In fact, the publication of the transcripts and the holding of public hearings would only assist the criminal investigation, since it would allow miners and their families an opportunity to review the testimony and possibly point to additional problems missed by people not as familiar with mining.

Rather, it is Massey Energy that will benefit from the information being kept private. Massey and company officials are facing several wrongful death lawsuits by family members of those killed. Keeping this information private places an additional burden upon these families, who will either have to proceed without the benefit of the information, hire their own investigators at enormous cost, or postpone their suits until such time as MSHA makes the information public.

When asked how it was possible that the Upper Big Branch mine was allowed to operate with so many safety violations, MSHA officials Joe Main and Kevin Stricklin defended the actions of MSHA investigators. Both Main and Stricklin said that inspectors are not on site all the time and that conditions change daily. In fact, Massey Energy and the UBB mine have a long pattern of violations, which MSHA officials ignored. If criminal charges are ever brought against Massey, company officials will argue that everything was fine when company officials visited the mine, and that local foremen were to blame.

The Longwall

At the time of the explosion, Massey was mining two major sections of the Upper Big Branch mine. At one section, they had a longwall machine operating and it was nearing the end of that area. At the same time, they were using a continuous miner to prepare another area for longwall mining. Investigators believe that the initial ignition of methane gas took place at what is called the tailgate section of the longwall.

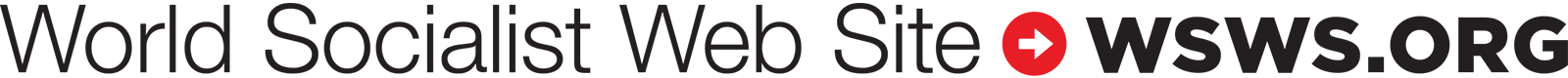

Longwall mining involves the digging of two parallel tunnels into the coal seam 1,000 feet apart, more than the length of three football fields. One of these tunnels is called the headgate and the other the tailgate. At the far end of the tunnels, a third tunnel is dug connecting the two; this will be the mine face. The shearer is placed on a track running between the headgate and tailgate, running up and down the track cutting into the coal.

Mining is done towards the entrance of the mine. Hydraulic jacks support steel covers that hold up the roof. As the coal is dug, the tracks, shearer and jacks are all moved forward. As the longwall miner digs through the coal seam and moves forward, the roof caves in behind the miner.

A diagram of longwall mining

A diagram of longwall miningThere are four major safety measures that need to be taken to prevent disasters: (1) ventilation, (2) maintaining the bits and shearer, (3) spraying water and (4) preventing the buildup of coal dust. Massey failed horribly in each of these areas, laying the conditions underground at the UBB mine for a disaster to happen.

Ventilation is needed both to bring fresh air to the miners and to dissipate and prevent the buildup of methane gas in the mine. Methane gas is naturally produced in similar geological processes that produce coal and often seeps out into mines. In addition, miners often run into pockets of gas embedded in a coal seam.

MSHA investigators have not completed their ventilation investigation of UBB, but in the months and weeks leading up to the explosion MSHA investigators had cited Massey multiple times for failure to maintain proper ventilation. Among those citations were having only about half the needed fresh air, as well as redirecting the exhaust air from one section of the mine into the air intake of another.

Just 30 minutes before the deadly blast, fire boss Michael Elswick called to the surface to say that the air was so poor and thick with coal dust that he couldn’t see to get out of the mine. His friend and fellow fire boss Scott Halstead, who was on the surface, testified that he was on his way into the mine to help Elswick out when the explosion occurred.

The shearer used on the longwall at the Upper Big Branch mine; many broken bits can be seen. Drill bits need to have a carbide tungstun tip to prevent sparking as they strike rock. Investigators believe that a spark ignited methane gas, which in turn set off a secondary coal dust explosion that killed the miners.

The shearer used on the longwall at the Upper Big Branch mine; many broken bits can be seen. Drill bits need to have a carbide tungstun tip to prevent sparking as they strike rock. Investigators believe that a spark ignited methane gas, which in turn set off a secondary coal dust explosion that killed the miners.The shearer, the part of the longwall that actually digs the coal, is a giant set of rotating drums with dozens of bits that dig the coal and rock. The bits are composed of a steel shank with a carbide tungsten tip. It is important that this tip be in place as a safety measure, because when a carbide tungsten tip hits rock it does not spark the way steel does. The seam being mined at the UBB mine was so narrow that the longwall machine was hitting sandstone continuously.

An examination of the shearer showed that most of the carbide tungsten tips were broken off the bits, leaving exposed steel to strike the rock and coal, causing a shower of sparks.

Next to each bit on the shearer, a water sprayer is attached to spray water onto the bit and coal as it digs. The water helps to keep the bits cool, keep down coal and rock dust and extinguish any sparks that come off the bits. Tests on the sprayers show that many were not working, some having been removed or purposefully blocked.

In addition to needing carbide tungston tips, the shearers are supposed to have water sprayers aimed at each bit, to keep the bits cool and to extinguish any sparks that are given off. Many of the sprayers were missing or not working.

In addition to needing carbide tungston tips, the shearers are supposed to have water sprayers aimed at each bit, to keep the bits cool and to extinguish any sparks that are given off. Many of the sprayers were missing or not working.A final step in preventing underground explosions is to control coal dust in the air and ground. Coal dust must be removed from along conveyor belts and pulleys that generate heat. “Rock dusting” must also be completed throughout the mine. “Rock dusting” is the spreading of ground-up rock dusk, like chalk, among the coal dust, which prevents the coal dust reaching explosive concentrations.

Tests of over 18,000 samples taken throughout the UBB mine after the disaster showed that 80 percent of the coal dust had not been rock dusted properly. In addition, logs recorded by miners as they did their pre-shift inspections showed repeatedly that coal dust was building up throughout the mine, but that rock dusting had been completed only in a few instances.

The 62 pre-shift inspections done on the day of the UBB explosion, and in the four days leading up to it in different parts of the mine, all showed the need for rock dusting to be done. Rock dusting was performed in only nine areas as a result of the inspection. All of this untreated coal dust turned a small methane ignition into a powerful and deadly disaster.

Many unanswered questions

More questions remain unanswered. According to the MSHA investigation, the longwall was taken out of service for maintenance around 11:00 a.m. and was not fixed until about 2:15 p.m. A call out of the mine at 2:30 p.m. reported that the shearer was at shed 115, headed towards the tailgate for mining. At the time of the explosion, half an hour later, seven of the miners killed had been leaving the mine and were already nearing the portal. Why was the longwall shift still working? Did the operators order the men to stay longer to make up for production missed while maintenance was done?

A second question is raised: Was a call made up to the surface at 3:00 p.m., possibly after the methane ignition, but before the coal dust explosion? Investigators know that miners working by the shearer had time to call miners who were at the headgate of the longwall, telling them of the methane ignition and having them cut power to the machine. Did those at the headgate section then have time to call to the surface to report the methane ignition?

Family members told investigators that they had been told by someone working in the office that a call had come in at 3:00 p.m., but MSHA officials responded that they have no record of such a call.

Another major question remaining is the suspicious activity of two company officials who traveled unsupervised throughout the mine for several hours. At the time of the explosion, 10 miners and company officials who were working on the surface of the mine entered the mine. On the way in, they discovered the man trip (personnel carrier) with the bodies of seven killed miners and another very badly injured miner.

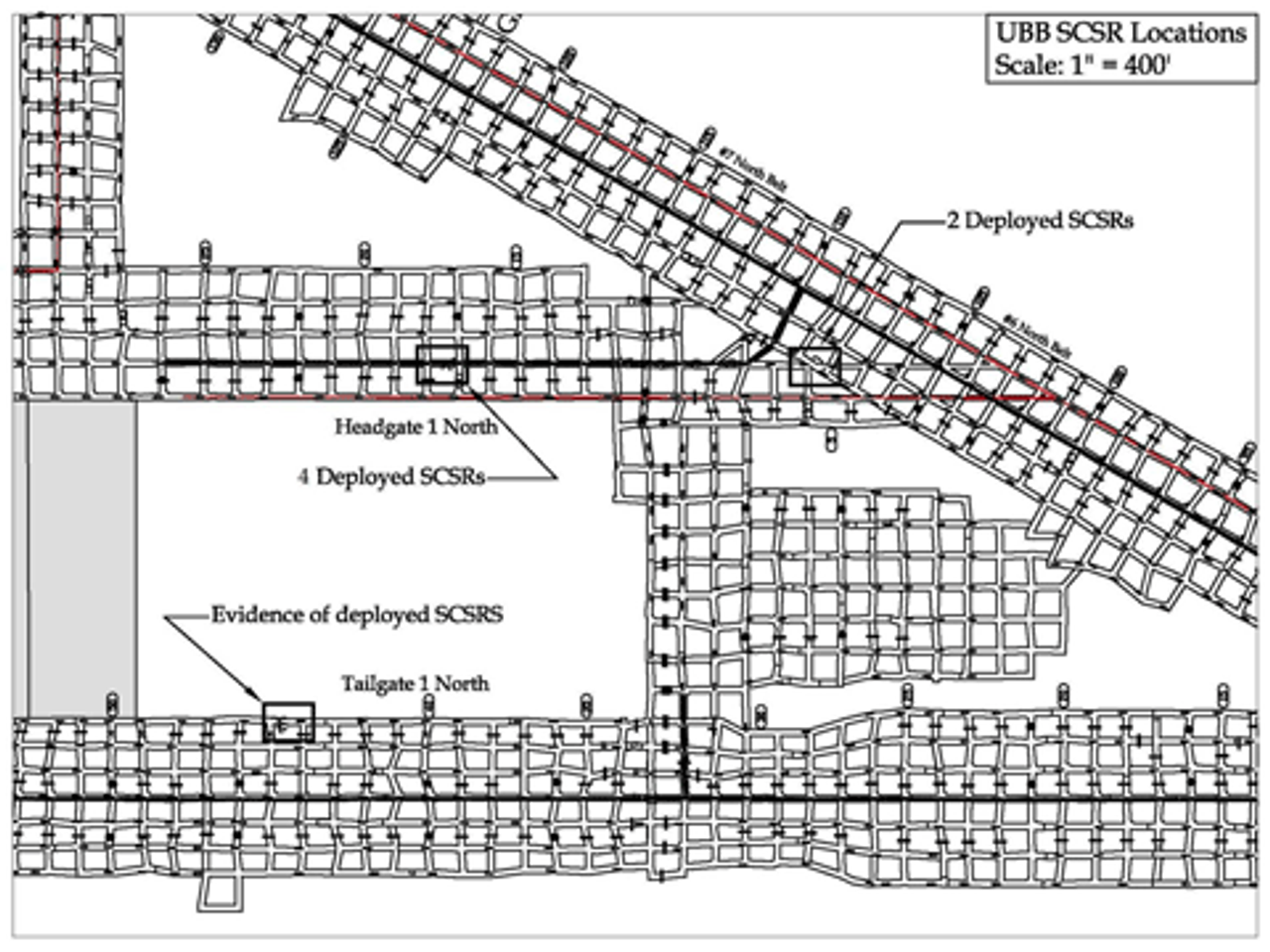

This map of a portion of the UBB mine shows the locations of discarded Self Contained Self Rescuers (SCSR) found in the mine. The noted locations of the discarded SCSRs show that the two company officials were in both the talegate and headgate sections of the longwall.

This map of a portion of the UBB mine shows the locations of discarded Self Contained Self Rescuers (SCSR) found in the mine. The noted locations of the discarded SCSRs show that the two company officials were in both the talegate and headgate sections of the longwall.At that point, those reentering the mine split up. Eight of those 10 men worked to bring the injured miner and the bodies of the seven others to the surface. Two company officials continued deeper into the mine and no details have been given as to their activities. A company statement says that they were seeking to rescue other injured miners. However, a map that shows the location of discarded or used Self Contained Self Rescue units (SCSR), devices used to provide oxygen to miners in an emergency, indicates that the two men only explored the longwall area.

In addition, discarded SCSR units were found near both the tailgate and headgate sections. The only way for the men to get from one to the other would be to either walk along the longwall face or around the longwall. In either case, they would have passed the bodies of miners killed. Yet they never reported the discovery of bodies to rescue crews and MSHA officials who had been called to the mine at the time of the explosion.

Furthermore, there is no evidence that the two searched in the area where the continuous miner was operating. That area would have been as likely as the longwall to be the cause of the explosion. If they believed that the explosion started at the longwall, then those miners working by the continuous miner would have had a better chance of surviving if they had had time to get to one of the rescue chambers in the mine.

The fact that the two officials concentrated on the longwall area indicates that they believed the explosion started at the longwall. The question is, why? Did they receive that 3:00 call as reported by the families, or did they base that conclusion on the troubles at the longwall during the day and previously? Neither of the two officials has testified to answer these types of questions; they are among the 18 Massey officials who have refused to answer questions.

Another major issue is the status of the investigation into the role of MSHA itself in the disaster. MSHA investigators had issued more than 600 citations over the previous 18 months. They were well aware of the problems with ventilation, the buildup of coal dust, and should have seen the state of the longwall and other mining equipment. Yet they took no action to shut the mine and protect the miners. A team of MSHA investigators had been in that area of the mine less then two weeks before the disaster. Joe Main defended the role of MSHA investigators and said there was an internal review only, but gave no indication of whether it had started and when or if its findings would be made public.

In addition to the lack of any serious investigation by MSHA, the Democratic Party at both the federal and state level has completely dropped any action to improve safety for miners. After a few hearings in the House of Representatives, Congress quietly dropped any proposed changes to the mine safety regulations. Joe Manchin, who was West Virginia governor at the time, said that the state would have its own independent investigation headed by Davitt McAteer, however that investigation has yet to take place.

Manchin has gone on to become a US senator, replacing the deceased Robert Byrd. Two weeks ago, Manchin was one of the main organizers of an anti-EPA rally in the state and he is part of a suit against the EPA for not granting permits for mountain top removal mining in several cases. Massey Energy is one of the largest largest mining companies in West Virginia involved in the top removal process.

Subscribe to the IWA-RFC Newsletter

Get email updates on workers’ struggles and a global perspective from the International Workers Alliance of Rank-and-File Committees.